Railway vehicles coupling

screw coupling

The

screw coupling, also known as UIC

coupling or UIC standard coupling, is the

coupling used in most European railway vehicles. It is a manual

coupling system, meaning coupling and uncoupling is done by hand.

Railway vehicles equipped with screw coupling

usually also have side buffers.

The

screw coupling, also known as UIC

coupling or UIC standard coupling, is the

coupling used in most European railway vehicles. It is a manual

coupling system, meaning coupling and uncoupling is done by hand.

Railway vehicles equipped with screw coupling

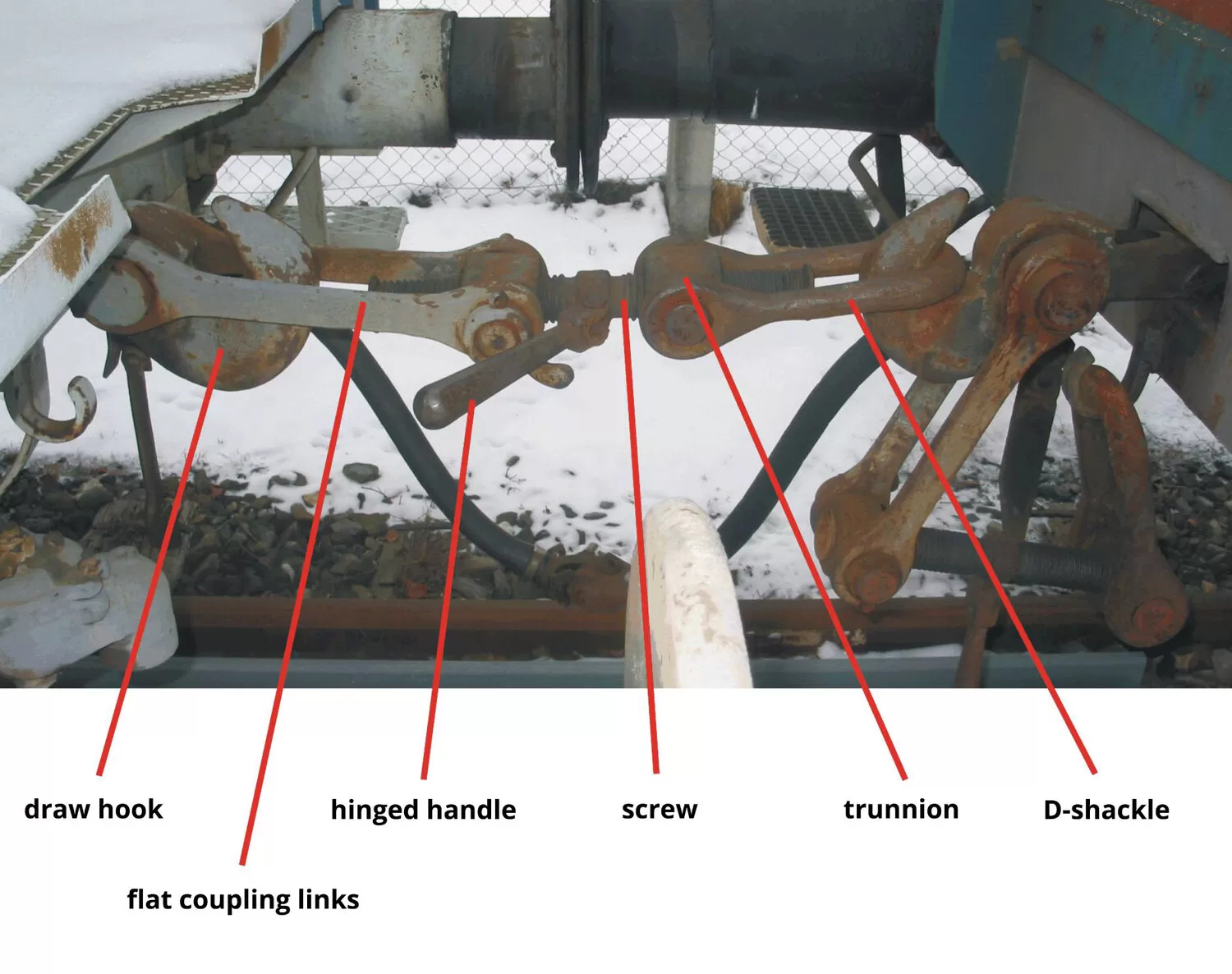

usually also have side buffers.A screw coupling is formed of a draw hook and a three-part chain formed by a flat coupling link (or a shackle in some older versions) fixed to the draw hook and connected to a shackle using a screw with a hinged (ball) handle in the middle.

For coupling or uncoupling, a railway employee must position himself between the vehicles. For coupling, he hangs the shackle in the draw hook of the opposite vehicle and turns the screw with the help of the hinged ball handle in order to shorten the length of the connection chain. For uncoupling, he turns the screw in the opposite direction to increase the length of the connection chain in order to be able to release the chuckle. Usually, the locomotive supports the process of coupling and uncoupling by pressing against the train during this time.

A properly connected screw coupling results in the buffers being slightly compressed: if the screw coupling is not sufficiently shortened, this can lead to violent jerking during the train ride, and on the contrary, if the screw coupling is too shortened, it can brake.

semi-automatic coupling

In the case of semi-automatic couplers, the

coupling of railway vehicles is executed automatically but

uncoupling is triggered by hand, in most cases by removing parts of

the latching mechanism with a handle.

The air pipes and electric connections are also coupled/uncoupled by hand.

The air pipes and electric connections are also coupled/uncoupled by hand.

automatic coupling

In the case of automatic couplers, the coupling of

railway vehicles is executed automatically, when the vehicles are

shunted in tight contact with a certain speed or force enabling the

latching mechanism to connect both couplers.

Additionally, the connections of brake pipes and, if equipped with such devices, connections for signals and electricity are also automatic.

Fully automatic couplings also allow for remote control uncoupling when required, thus no manual interference with the couplers is necessary.

Additionally, the connections of brake pipes and, if equipped with such devices, connections for signals and electricity are also automatic.

Fully automatic couplings also allow for remote control uncoupling when required, thus no manual interference with the couplers is necessary.

AK69

In 1925, the International Union of Railways ("Union Internationale

des Chemins de fer" - UIC) sets up a committee "Automatic Couplers"

but following the political situation in that period no results

could be achieved. In 1956, the committee is established once

again. Works resulted in the AK69 central buffer

automatic coupler designed by Unicupler GmbH.

AK69 couplers can automatically connect

two air lines and up to six electrical lines (due to the

significant mechanical slack, the line couplings are highly complex

and mounted on soft springs to compensate for the slack). They are

designed for a coupling speed of 1.5 km/h and permit coupling up to

a height offset of ± 140 mm and a transverse offset of ± 220 mm.

The maximum tolerable forces are 2000 kN for compressive and 1000

kN for tensile forces.

AK69 couplers can automatically connect

two air lines and up to six electrical lines (due to the

significant mechanical slack, the line couplings are highly complex

and mounted on soft springs to compensate for the slack). They are

designed for a coupling speed of 1.5 km/h and permit coupling up to

a height offset of ± 140 mm and a transverse offset of ± 220 mm.

The maximum tolerable forces are 2000 kN for compressive and 1000

kN for tensile forces.

NB: These couplers are almost identical to INTERMAT automatic couplers developed during the same period by VEB Waggonbau Bautzen under the supervision of the Organization for Cooperation of Railways (OSShD). A common group UIC/OSShD was even created to work in further standardisation and optimisation to develop an unique automatic coupler for the European market based on the two designs.

Despite the fact that AK69 couplers proved their reliability and some definite operational advantages compared to standard screw couplings with side buffers, their European-wide introduction is postponed again and again. This is due mainly to logistical (the coupling is not compatible with standard screw couplings thus a simultaneous changeover would have been necessary for the entire vehicles fleet) and financial (the acquisition costs are higher compared with standard screw couplings) reasons.

In Switzerland, AK69 couplers are installed on the rolling stock used for the Swiss Express service: 8x Re 4/4II electric locomotives of the Swiss Federal Railways - SBB CFF FFS fleet and all EW III passenger coaches. After the service is abandoned in 1982, all Re 4/4II electric locomotives dedicated for the service and some coaches are refitted with screw couplings but most of the EW III passenger coaches keep their AK69 automatic couplers even after their transfer to Bern–Lötschberg–Simplon Railway - BLS in 2004.

In Germany, the AK69 automatic coupler are installed on locomotives and freight wagons used for iron ore transports between Hamburg and Salzgitter. 20x Class 151 electric locomotives and around 400x freight wagons owned today by DB Cargo are converted from 1976. The conversion is required as the total mass of the ore trains (up to 6000 t) is too heavy for standard screw couplings (designed for trains around 3000 t).

AK69 couplers can automatically connect

two air lines and up to six electrical lines (due to the

significant mechanical slack, the line couplings are highly complex

and mounted on soft springs to compensate for the slack). They are

designed for a coupling speed of 1.5 km/h and permit coupling up to

a height offset of ± 140 mm and a transverse offset of ± 220 mm.

The maximum tolerable forces are 2000 kN for compressive and 1000

kN for tensile forces.

AK69 couplers can automatically connect

two air lines and up to six electrical lines (due to the

significant mechanical slack, the line couplings are highly complex

and mounted on soft springs to compensate for the slack). They are

designed for a coupling speed of 1.5 km/h and permit coupling up to

a height offset of ± 140 mm and a transverse offset of ± 220 mm.

The maximum tolerable forces are 2000 kN for compressive and 1000

kN for tensile forces.NB: These couplers are almost identical to INTERMAT automatic couplers developed during the same period by VEB Waggonbau Bautzen under the supervision of the Organization for Cooperation of Railways (OSShD). A common group UIC/OSShD was even created to work in further standardisation and optimisation to develop an unique automatic coupler for the European market based on the two designs.

Despite the fact that AK69 couplers proved their reliability and some definite operational advantages compared to standard screw couplings with side buffers, their European-wide introduction is postponed again and again. This is due mainly to logistical (the coupling is not compatible with standard screw couplings thus a simultaneous changeover would have been necessary for the entire vehicles fleet) and financial (the acquisition costs are higher compared with standard screw couplings) reasons.

In Switzerland, AK69 couplers are installed on the rolling stock used for the Swiss Express service: 8x Re 4/4II electric locomotives of the Swiss Federal Railways - SBB CFF FFS fleet and all EW III passenger coaches. After the service is abandoned in 1982, all Re 4/4II electric locomotives dedicated for the service and some coaches are refitted with screw couplings but most of the EW III passenger coaches keep their AK69 automatic couplers even after their transfer to Bern–Lötschberg–Simplon Railway - BLS in 2004.

In Germany, the AK69 automatic coupler are installed on locomotives and freight wagons used for iron ore transports between Hamburg and Salzgitter. 20x Class 151 electric locomotives and around 400x freight wagons owned today by DB Cargo are converted from 1976. The conversion is required as the total mass of the ore trains (up to 6000 t) is too heavy for standard screw couplings (designed for trains around 3000 t).

Discussion forum