Source: marklinfan.com

Also known as:

Vehicle type:

Registration country:

1928

New passengers could be attracted and a class of traveller which had, practically, been lost, could be regained by putting on light, adaptable, fast-running motor coaches and this without making any extension of the existing stationary power plants. The main objective pursued was the filling of gaps in the timetable and the improvements of connections between important traffic centres. Some obsolete principles had to be reviewed. For example, it is in the interest of travellers to have fast-travelling motor coaches without large luggage compartments, the filling and emptying of which takes up precious time. Also, already at the time, coaches with several classes were in much less demand from the travelling public than formerly.

As early as 1928, Brown Boveri began studying light motor coaches following the fundamental principles summarised herewith:

- reductions of the dimensions and power of the motor-coach which had tended to develop along the lines of electric locomotive designs in regards to power and appearance;

- light weight to allow of rapid starting and low power consumption;

- use made of the driver as a ticket controller as well;

- use made of special structural steel for the body and framework of the coach;

- light metals used for all those parts which are only slightly stressed, as well as for the fittings;

- low swung body to allow of easy access and egress while reducing the overall height of the body proper;

- rigorous suppression of all accessory compartments which do not meet the main object of the coach;

- elimination of tractive and buffer gear and its replacement by simple auxiliary traction hooks;

- modern interior fittings especially comfortable seating;

- utilisation of rubber cushioning for deadening noise and vibration;

- automatic door-closing gear;

- only one current collector with broad contact piece, for high travelling speeds;

- special roof-type fuse to replace the cumbrous high-voltage circuit breaker;

- adaptation of the motor drive for high speeds;

- far-reaching concentration of electrical equipment on and above the bogies proper, which allows of keeping the body of the coach low and, thus, of having low entry steps (this also lightened the body of the coach);

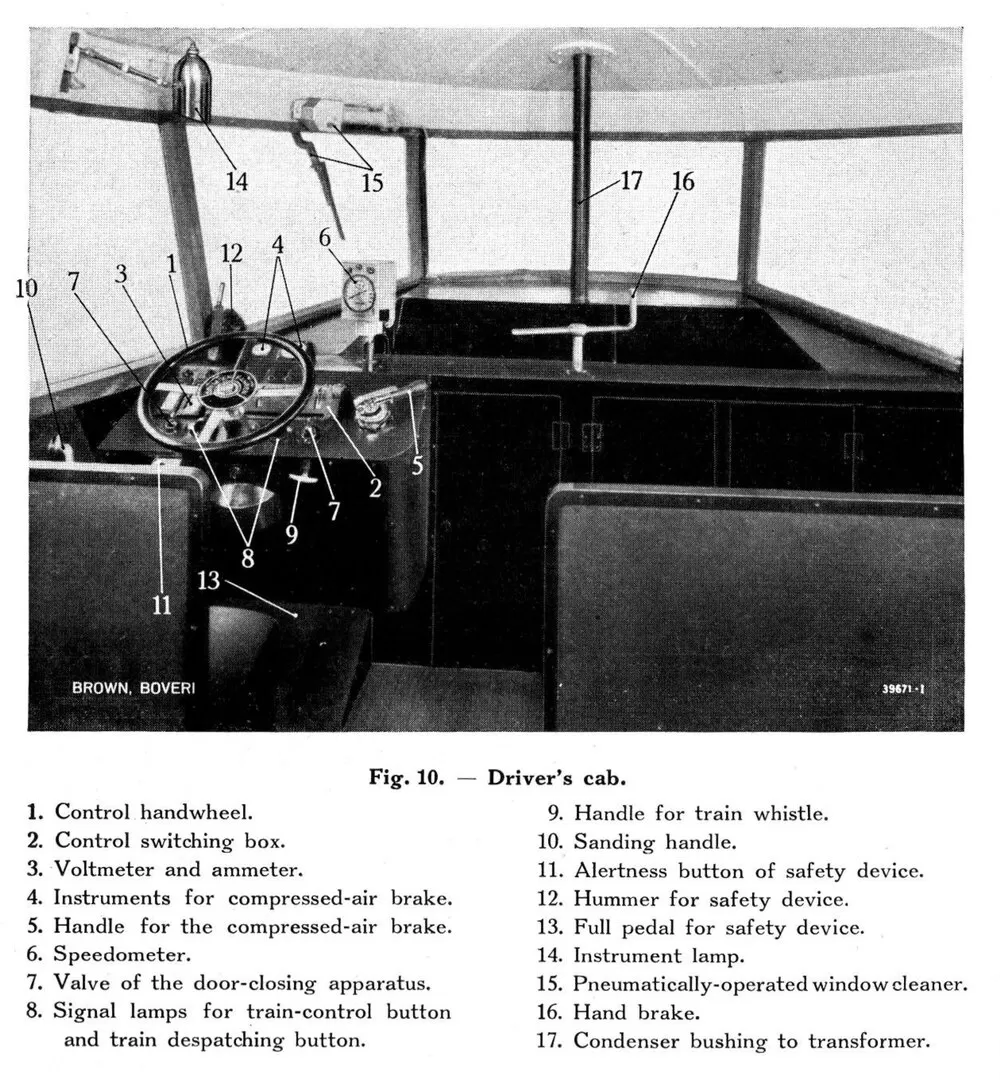

- much simplified manipulation of apparatus for travelling and braking;

- adaptation of safety device to the seated position of the driver;

- efficient electric DC braking, independent of contact wire;

- electric air heating to reduce the time required to heat up the coach and to reduce cost of upkeep.

Sources: The Brown Boveri Review (August 1935)

1933

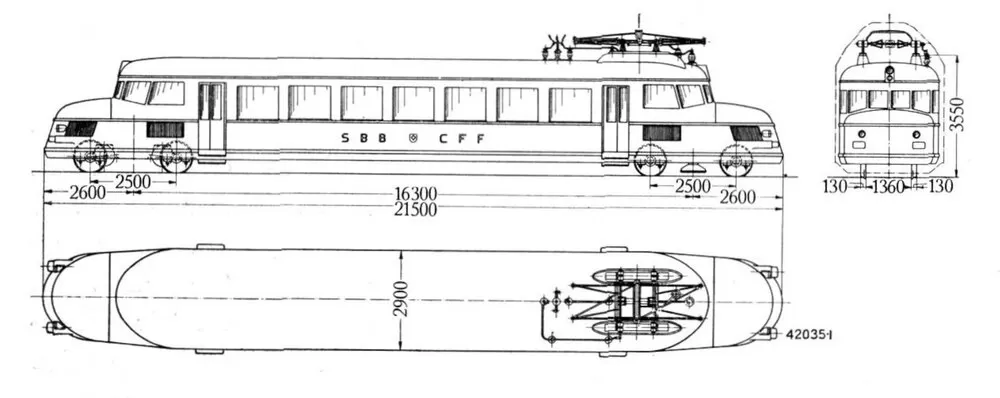

The low swung coach body, built of special structural steel and aluminium, is supported by the two bogies, each of which has two axles of 2'500 mm wheel base. The two ends of the coach body project beyond the bogies, the said projections are low in design and serve to carry the electric equipment. In view of the high speeds of the coach, the coach body is rounded off as much as is possible so as to offer less resistance to wind. The diminution of the resistance to travel is about 25% as compared to standard sharp-angled coach design with vertical front wall, which valuable quality was demonstrated at the first trial runs.

The coach bodies are built with a double roof in such a manner that the braking resistances could be lodged between the two. This allowed of imparting a stream line to the coach body. The ventilation slots which lead cooling air to the resistances are placed at right angles to the axis of the coach and are designated to conform to the rounding of the coach roof.

Weight has been economised on the bogies as well as on the coach. One bogie is a running bogie only and carries the transformer while the other one has the two driving motors built into it.

The safety apparatus is combined with the apparatus for automatic signal train control on the line, so that with one-man control of the coach the highest degree of safety is attained. The seated position of the driver meant a special foot-pedal design. In the place of the toe pedal common to locomotives of the Swiss Federal Railways (SBB CFF FFS), a full pedal is used here on which both feet can rest comfortably. The fulcrum in the middle of the pedal is so chosen that, the driver being in the ordinary position, must depress the toes slightly. If the driver, being unwell, relaxes this pressure, the pedal contact opens the circuit of the safety current and thus causes the current to the driving motors to be cut off while causing the compressed air brake to act. When the pedal is properly adjusted, this arrangement gives great security.

There is sitting accommodation for 70 passengers and standing room for 30 additional passengers while the window apertures are wide, thus the coaches are very comfortable for travellers.

The heating of the coach by air does much to make it cleaner and healthier. By lodging the central-heating bodies under the coach floor, an unencumbered through-floor space is attained which is easy to keep clean. With the introduction of about 600 m3 of air into the coach per hour, a very slight super-pressure is brought about which gives rise to a continuous renewing of the air without opening the windows, which is so desirable in winter. The built-in thermostat had the double duty of keeping the temperature in the coach constant and of economising heating current.

At the same time, 2 diesel railcars are ordered. These will be registered as CLm 2/4.

Sources: The Brown Boveri Review (August 1935)

1935

March 15

1935

April 16

On the same day it travelled to Zürich on which trip the speed was increased to 125 km/h. On the following days, a series of continuous running tests are carried out on the Zürich - Romanshorn line section.

It enters regular service on May 15th, 1935.

Sources: The Brown Boveri Review (August 1935)

1936

1937

Sources: https://www.lokifahrer.ch/Lokomotiven/Loks-SBB/Rote-Pfeile/SBB-CLe_2-4.htm

1938

1946

Sources: https://www.lokifahrer.ch/Lokomotiven/Loks-SBB/Rote-Pfeile/SBB-CLe_2-4.htm

1952

May 1

On

May 1st, 1952, unit RCe 2/4 601 was on a private trip to Valais for

employees of the Sandoz company in Basel. At 3:30, while reaching

Villeneuve at full speed, the railcar collided head-on with

locomotive Ae 3/6I 10687 that was manoeuvring.

On

May 1st, 1952, unit RCe 2/4 601 was on a private trip to Valais for

employees of the Sandoz company in Basel. At 3:30, while reaching

Villeneuve at full speed, the railcar collided head-on with

locomotive Ae 3/6I 10687 that was manoeuvring.Despite the engine driver's efforts to alert the passenger and move them to the back of the railcar, 3 people died and many more (including the driver) are seriously injured. While the Ae 3/6I 10687 electric locomotive is only slightly damaged, the railcar suffers extensive damage.

Following the accident, unit RCe 2/4 601 will be rebuilt as RAe 2/4 1001. By the time, it is clear that the railcars are no longer suitable for regular service but there is again an increased demand for railway excursions and these units continue to be popular among the passengers. An increase in confort is expected though and the decision is taken to upgrade the units to 1st class.

Sources: https://www.lokifahrer.ch/Lokomotiven/Loks-SBB/Rote-Pfeile/SBB-CLe_2-4.htm

1953

Sources: https://www.lokifahrer.ch/Lokomotiven/Loks-SBB/Rote-Pfeile/SBB-CLe_2-4.htm

Do you have additional informations regarding this vehicle?

Help us writing the history of CLe 2/4! Your knowledge is precious for us and the entire community, do not hesitate to share your facts, photos or videos:

Latest update on the 27th of September 2020 at 16:59

Contributor(s): Tudor C.

Discussion forum